Speed Doors

Speed doors are an advanced solution for various industrial and commercial applications. They are designed to open and close rapidly, providing numerous advantages in terms of efficiency, safety, and energy savings.

Benefits of Speed Doors

- Increased Efficiency: High-speed doors open and close much faster than traditional doors, reducing the time needed for vehicles and personnel to move through. This can significantly improve workflow and productivity.

- Energy Savings: By minimizing the time the door remains open, high-speed doors help maintain the internal climate, reducing energy costs for heating or cooling.

- Enhanced Safety: These doors often come with advanced safety features such as sensors and automatic reversing mechanisms to prevent accidents and injuries.

- Durability: Made from robust materials like reinforced PVC or aluminum, high-speed doors are built to withstand frequent use and harsh conditions.

- Hygiene Control: In environments such as food processing or pharmaceuticals, high-speed doors help maintain hygiene by reducing the risk of contamination.

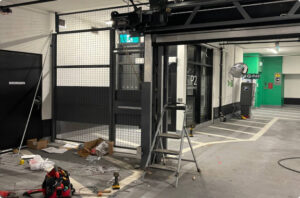

Types of Speed Doors

- Roll-Up Doors: These doors roll up into a compact coil above the opening, saving space and allowing for quick access.

- Fold-Up Doors: These doors fold up in sections, providing a sturdy and reliable barrier.

- Sliding Doors: High-speed sliding doors move horizontally, ideal for spaces where vertical clearance is limited.

Materials and Construction

High-speed doors are constructed from various materials to suit different needs:

- PVC: Lightweight and flexible, ideal for environments requiring frequent cleaning.

- Aluminum: Provides strength and durability, suitable for industrial settings.

- Stainless Steel: Used in environments where hygiene and corrosion resistance are critical.

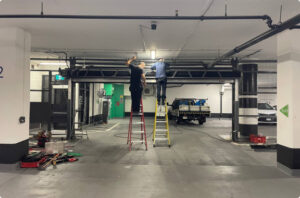

Operating Mechanism

Speed doors are equipped with powerful motors and control systems that ensure rapid and smooth operation. They often include features such as:

- Sensors: Detect motion and automatically open the door, enhancing safety and convenience.

- Control Panels: Allow for easy operation and customization of door settings.

- Emergency Release: Ensures the door can be opened manually in case of power failure.

Applications

Speed doors are used in various industries, including:

- Manufacturing: To streamline operations and improve efficiency.

- Warehousing: To facilitate quick and easy access for forklifts and other vehicles.

- Food Processing: To maintain hygiene and control temperature.

- Pharmaceuticals: To ensure a clean and controlled environment.

Conclusion

Speed doors are a practical and efficient solution for many industrial and commercial applications. They offer numerous benefits, including increased efficiency, energy savings, enhanced safety, and improved hygiene. Their robust construction and advanced features make them a valuable addition to any facility.