Repair Automation Systems for Sliding Gates

Automation systems for sliding gates provide a modern and efficient solution for controlling access to residential, commercial, and industrial properties. However, like any mechanical system, they can experience issues that require repair. This article explores common problems, maintenance tips, and the importance of professional repair services for sliding gate automation systems.

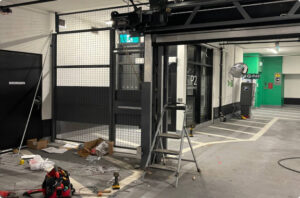

Common Issues with Sliding Gate Automation Systems

- Motor Malfunctions: The motor is a critical component of automated sliding gates. Electrical faults or motor burnout can prevent the gate from operating correctly. Regular maintenance and timely repairs are essential to keep the motor in good condition.

- Control Panel Failures: The control panel serves as the brain of the gate system. Issues such as faulty wiring, sensor malfunctions, or software glitches can disrupt the gate’s functionality. Professional inspection and repair are often required to address these issues.

- Track and Roller Problems: The track and rollers guide the movement of the sliding gate. Misaligned tracks or worn-out rollers can cause the gate to jam or operate unevenly. Ensuring the tracks are clean and properly aligned, and replacing worn-out rollers, can prevent these issues.

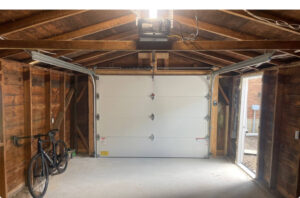

- Obstructed Mechanism: Debris such as leaves, dirt, or small stones can obstruct the gate’s mechanism, causing it to jam. Keeping the mechanism clean and free of obstructions is crucial for smooth operation.

- Safety Sensor Issues: Automated sliding gates rely on safety sensors to detect obstacles and prevent accidents. Malfunctioning sensors can compromise safety and disrupt the gate’s operation. Regularly checking and calibrating the sensors is essential.

Importance of Regular Maintenance

Regular maintenance of sliding gate automation systems is crucial for several reasons:

- Prevents Unexpected Breakdowns: Routine inspections and maintenance can identify potential issues before they become major problems, reducing the risk of unexpected breakdowns.

- Enhances Security: Well-maintained gates provide better security, protecting valuable assets and preventing unauthorized access.

- Improves Efficiency: Properly functioning gates ensure smooth operations, reducing delays and improving overall efficiency.

- Extends Lifespan: Regular maintenance can significantly extend the lifespan of the gates, providing better returns on investment.

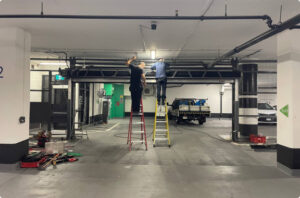

When to Call a Professional

While some minor issues can be addressed through DIY methods, many sliding gate automation problems require the expertise of a professional. Here are some signs that it’s time to call a repair service:

- Unusual Noises: If you hear grinding, squeaking, or banging sounds when operating the gate, it’s a sign that something is wrong.

- Slow Response: If the gate is slow to respond to commands or moves unevenly, professional inspection and repair are necessary.

- Visible Damage: Any visible damage to the gate, tracks, or control systems should be addressed promptly to prevent further issues.

Choosing the Right Repair Service

Selecting a reliable repair service is essential for ensuring quality repairs and maintenance. Consider the following factors when choosing a service provider:

- Experience and Expertise: Look for companies with extensive experience in sliding gate automation repair and a proven track record.

- Customer Reviews: Check online reviews and testimonials to gauge the quality of service and customer satisfaction.

- Availability: Choose a service provider that offers prompt and reliable service, especially in emergency situations.

- Warranty: Ensure that the repair service offers a warranty on their work, providing peace of mind and protection against future issues.

Conclusion

Maintaining automation systems for sliding gates is essential for the smooth operation and security of any property. Regular maintenance, timely repairs, and choosing the right service provider can help ensure that your sliding gate automation systems remain in optimal condition, providing reliable performance and protection.